- response@yashdeep.net

- 7506306663

Helical gears are meshed parallelly but their teeth are made to angular to the gear axis. Helical gears having their teeth angular, are continuously engaged with each other, irrespective of the teeth angles. Also needless to say that the torque they deliver is more than spur gears.

Helical gears are manufactured with accurate helix angle selection. Gear designer and machine setter has to give attention for indexing, differential and cutter angle so that helix angle should be cut accurately. Speed of machine should be controlled properly, so that load on cutters can be minimized. While setting top and bottom limits of hob travel, the teeth should be cut totally.

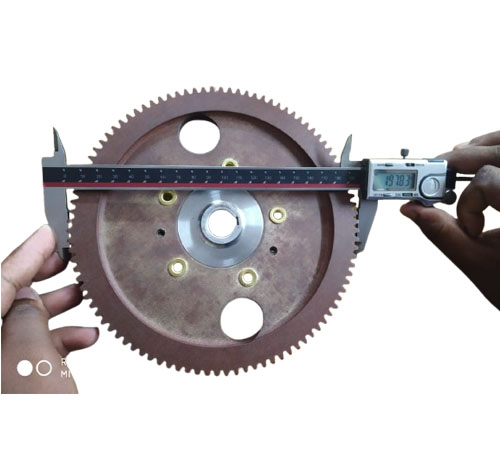

We at Yashdeep engineering cut helical teeth from 0.3 module to 6 module at the helix angle up to 45 degrees, both left-hand and right-hand teeth shape. We make sure that both gears mesh properly. We cut helical teeth on Carbon steel, Forged steel, Case hardening steel, Hylum, poly acetal (plastic), aluminium etc.

Helical gears we design and manufacture perfectly mesh with each other. Generally we manufacture these gears in bulk quantity, but we can provide less quantity for our regular customers.