- response@yashdeep.net

- 7506306663

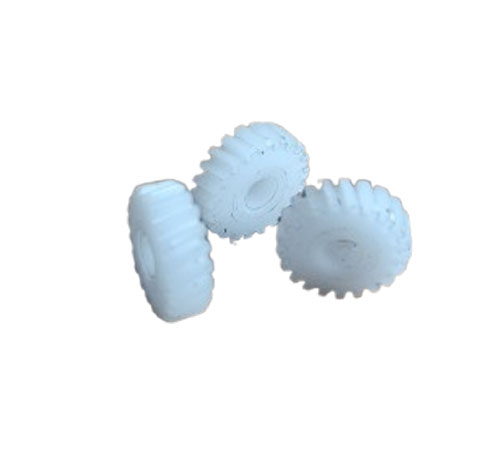

General term plastic gears mean gear made up of soft material like nylon, polyacetal, Delrin etc. It can take comparatively less torque, no noise. Gears made up of these materials are self-lubricative, hence separate lubrication arrangement is not required. Plastic gears can be made spur, helical, worm wheels, Bevel and so on. Generally, two processes are used to manufacture plastic gears, Molding process and Hobbing process.

Molding process : This process is applicable where gear quantity requirement is huge. Gears made through this process are used where accuracy is not a constraint, but quantity of gears and price of each gear is a concern. Initial expenses are more as we need to make mold of product. If product quantity requirement is huge then this initial cost is adjusted in production. Toy gears are generally made through this process only. Advantage of this process is that, complex shapes of product can be made and considerable material can be saved.

Hobbing process : This process is used where small quantity with great accuracy is required to manufacture. Almost all type of gears can be made through this process. The hobbing or gear shaping process is same as to manufacture metal gears. Advantage of this process is that small quantity can be made with great accuracy. Inventory is no concern as special mold is not require.

We at Yashdeep engineering services, cut all type of plastic gears in designated material like Delrin, poly acetal, nylon etc. from 0.3 module to 6 module and the helix angle up to 45 degrees, both left-hand and right-hand. We make gear blanks and cut teeth on almost all type of plastic material.

We design and manufacture all types of plastic gears for our old and new customers.